Found 1 results

Article

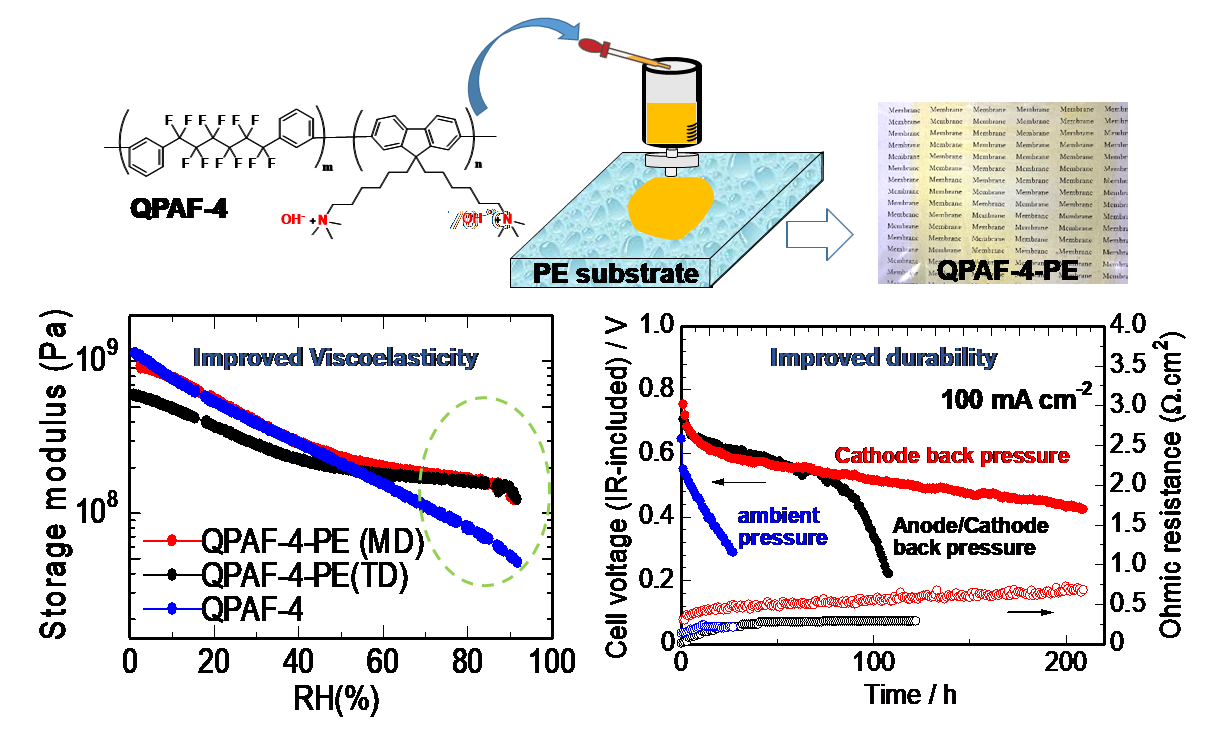

25 September 2023Anion Exchange Membrane Reinforced with Polyethylene Substrate for Alkaline Fuel Cell Applications

To enhance mechanical robustness of our in-house anion exchange membrane (QPAF-4), the reinforcement technique was applied using ozone-treated, porous polyethylene (PE) thin film (Toray SETELA) as a substrate. Homogenous and flexible reinforced membranes (QPAF-4-PE, 15–20 µm thick) were obtained by bar-coating method. The cross-sectional SEM image and EDS analysis revealed triple-layered (sandwich-like) structure without detectable pinholes. The QPAF-4-PE with ion exchange capacity (IEC) of 1.48 meq·g−1 exhibited lower water uptake (15 wt% at 90% relative humidity) and slightly lower hydroxide ion conductivity (71 mS·cm−1 at 80 ℃) than those of the pristine QPAF-4 (IEC = 1.84 meq·g−1, 25 wt% water uptake and 82 mS·cm−1 of the conductivity). The reinforced QPAF-4-PE exhibited slightly higher viscoelasticity (particularly, in MD direction) due to the suppressed water absorbability. Furthermore, the elongation at break increased by 9.8% in TD direction and 6.3% in MD direction. An H2/O2 fuel cell using QPAF-4-PE as membrane was investigated at different back-pressure, in which the cell with 100 kPa back-pressure onto the cathode side only achieved the maximum performance (176 mW·cm−2 at current density of 364 mA·cm−2) and the longest durability for (>200 h) at a constant current density of 100 mA·cm−2 maintaining 0.43 V of the cell voltage (67% remaining). The durability was eight times longer than that with ambient pressure and two times longer than that with back-pressure on both sides.